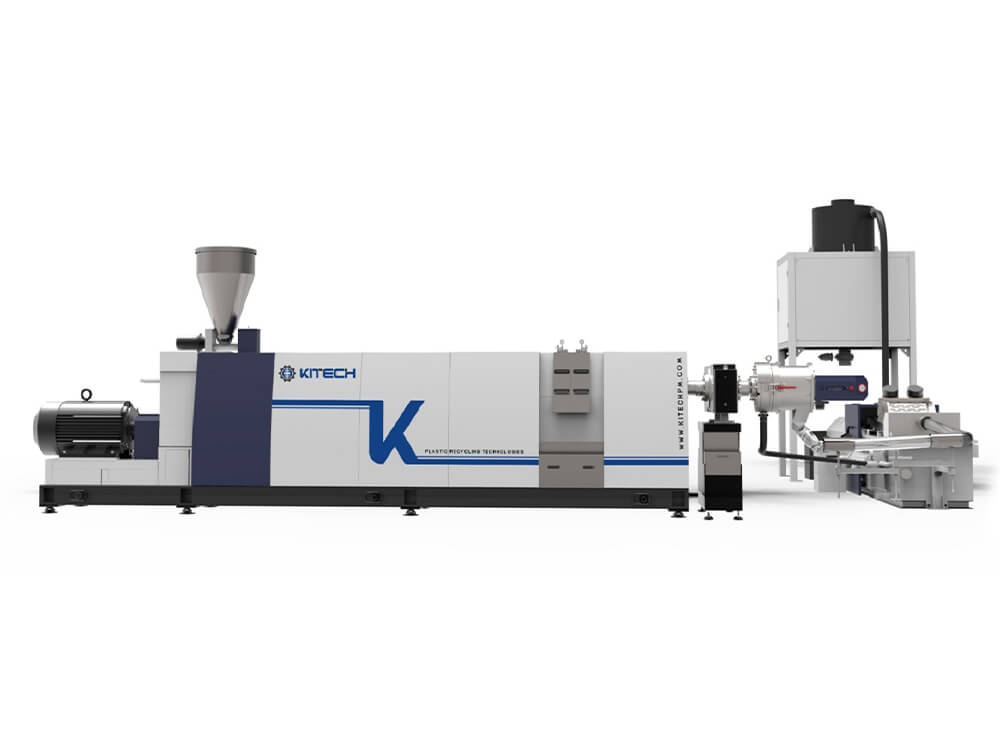

JIANGSU KITECH MACHINERY CO.,LTD

Plastic granulator is a common mechanical equipment. In the process of daily operation of plastic granulator, various failures will inevitably occur, which will affect the normal production of the machine. The following is an analysis of common plastic granulator failures And provide the cause, treatment method and failure analysis for your reference and reference!

Causes: uneven feeding, damage to the main motor bearing or poor lubrication, no heating. A certain section of the heater fails or the phase is wrong, the screw adjustment pad is wrong, and the components interfere.

Disposal method: troubleshoot, check the feeder, and replace the bearing if necessary. Overhaul the main motor and replace the heater if necessary. Check whether each heater is working normally, pull out the screw rod to check whether there is any interference with the screw rod, and check the adjustment pad.

Cause: The driving sequence is wrong, check whether the fuse is burnt; there is a problem with the thread of the main motor; the interlocking device related to the main motor works.

Disposal method: Restart the vehicle in the correct driving sequence, check the sequence, check the circuit of the main motor, and check the state of the interlocking device related to the main motor. The oil pump does not start, check whether the lubricating oil pump starts. The motor cannot be turned on. Turn off the main power supply and wait for 5 minutes before restarting. The inverter has not fully discharged the induction power. Check whether the emergency button is reset.

Cause: Poor plasticization of materials. A section of the heater is not working or the molecular weight distribution of the plastic is wide. The operating temperature setting is low and unstable. There may be foreign matter that does not melt easily.

Disposal method: replace if necessary, check the heater, and consult with the craftsman if necessary. Verify the temperature setting of each section; increase the temperature setting value; clean and check the extrusion system and machine head.

Causes: large torque, lack of heating time, a section of the heater does not work.

Disposal method: If it is not easy, use a hand wheel when driving, then extend the heating time or check whether the heaters in each section are working normally. \

Cause: The main motor bearing is damaged. One of the thyristors in the thyristor rectification circuit of the main motor is damaged.

Disposal method: replace the main motor bearing. Check and clean the extrusion system.