ABS PS Regrind

Intelligent Control

High Productivity

Low energy consumption

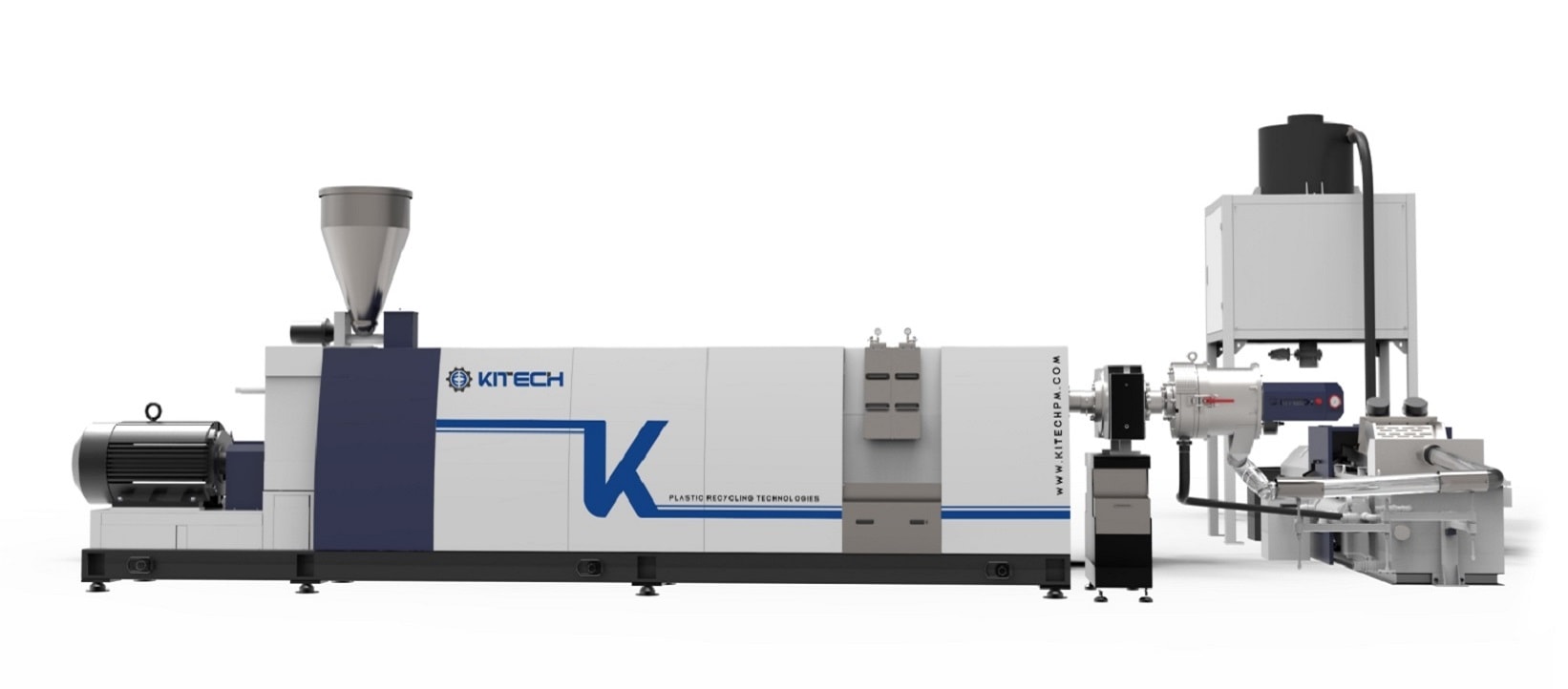

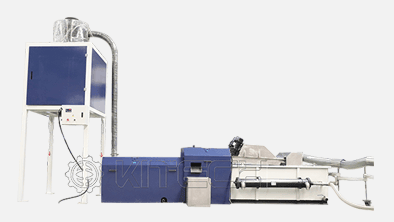

The KSP series single screw plastic regrind pelletizing system combines quantitative feeding, high efficiency extruder, different type of filter and different types of pelletizer by modular design. It provides best solution for PE, PP, PS, ABS, PC, PET, PA and many other rigid plastic regrind recycling.

ABS PS Regrind

PE PP flakes

Squeezed Film

| Machine Model | KSP |

|---|---|

| Brand | KITECH |

| Applicable material | HDPE, LDPE, PP, PS, ABS, PC, PET, PA |

| Capacity | 200-1200KG/H |

| Screw diameter | 80-200MM |

| Screw design | Single Screw |

| L/D ratio | 25-35 |

| Screw rpm | 90-150 |

| Screw material | 38CrMoAl |

| Gearbox type | High torque vertical |

| Motor brand | WEG/SIEMENS |

| Degassing zone | 2 |

| Pelletizer type | Water ring pelletizer |

| Total power | 130-529KW |

| Delivery time | 2-4 months ready for inspection |

| Guarantee | 1 year |

| Certificate | CE |

WE PROVIDE THE BEST PLASTIC RECYCLING SOLUTION

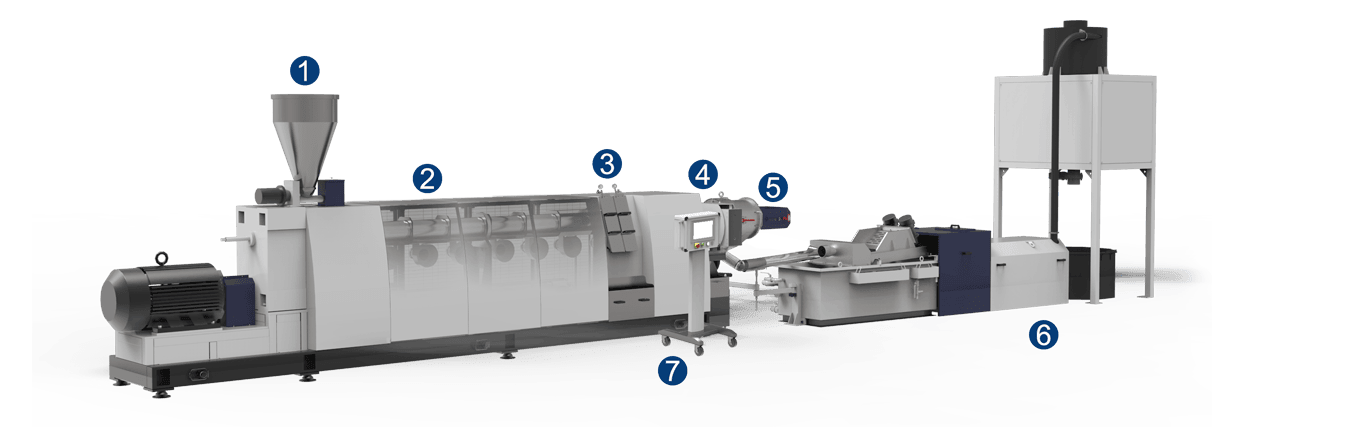

Dosing feeder with PLC intelligent controller, which ensures the extruder run steadily.

High efficiency barrel and screw used for extruder with excellent plasticizing result and high output capacity. Adopt high wear resistant alloy material to ensure 1.5 times service life of normal one.

Force double vacuum degassing system to get rid of the low molecular, moisture and printing ink effectively, make sure high quality output pellets.

Plate type, piston type, back flush type and automatic self-cleaning type filter, you have different choice according to impurity contents in material and your habit.

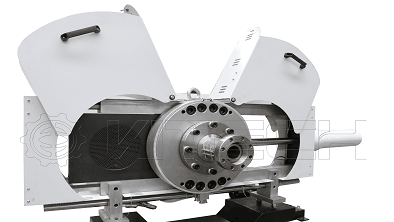

New European design water ring pelletizer, Cutting speed of pelletizer controlled automatically by PLC according to the pressure of die head, which could achieve the uniform size for output pellets.

Vibration dryer combined with horizontal type centrifugal dryer to get well dried final granules.

Thanks to Siemens PLC and HMI, KCP series recycling pelletizing machine provides high intelligent operation system which is easy to operate and save manpower.

KITECH IS COMMITTED TO BECOMING A WORLD-RENOWNED RECYCLING EQUIPMENT MANUFACTURER.

| type | KSP100 | KSP120 | KSP150 | KSP180 | KSP200 | |

|---|---|---|---|---|---|---|

| Capactity (KG/H) | 300-380 | 400-500 | 600-750 | 800-950 | 1000-1200 | |

| Energy consumption (kwh/kg) | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | |

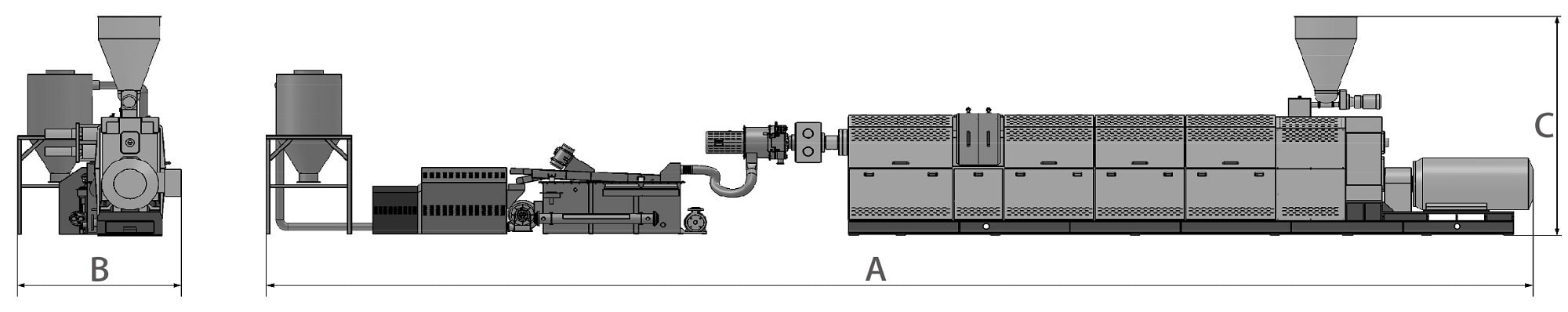

| A / Length (mm) | 12,500 | 13,800 | 14,900 | 15,200 | 16,500 | |

| B / Width (mm) | 2,500 | 2,500 | 2,500 | 3,300 | 3,300 | |

| C / Height (mm) | 3750 | 3980 | 4250 | 4460 | 4850 | |

| Extruction | Screw diameter (mm) | Φ100 | Φ120 | Φ150 | Φ180 | Φ200 |

| U/C | 25-35 | 25-35 | 25-35 | 25-35 | 25-35 | |

| Motor power (KW) | 90-110 | 132-160 | 160-200 | 250-315 | 315-355 | |

| Filter (options) | Two position plate type | ◉ | ◉ | ◉ | ◉ | ◉ |

| Two position piston type | ◯ | ◯ | ◯ | ◯ | ◯ | |

| Back flush piston type | ◯ | ◯ | ◯ | ◯ | ◯ | |

| Automatic self-cleaning type | ◯ | ◯ | ◯ | ◯ | ◯ | |

| 2nd Extruder (Optional) | Screw diameter (mm) | Φ120 | Φ150 | Φ150 | Φ180 | Φ200 |

| U/C | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | |

| Motor power (KW) | 37-45 | 45-55 | 55-75 | 75-90 | 90-110 | |

| Downstream (options) | Water ring pelletizer | ◉ | ◉ | ◉ | ◉ | ◉ |

| Strand pelletizer | ◯ | ◯ | ◯ | ◯ | ◯ | |

| Automatic strand pelletizer | ◯ | ◯ | ◯ | ◯ | ◯ | |

| Underwater pelletizer | ◯ | ◯ | ◯ | ◯ | ◯ | |

◉ Standard ◯ Alternative