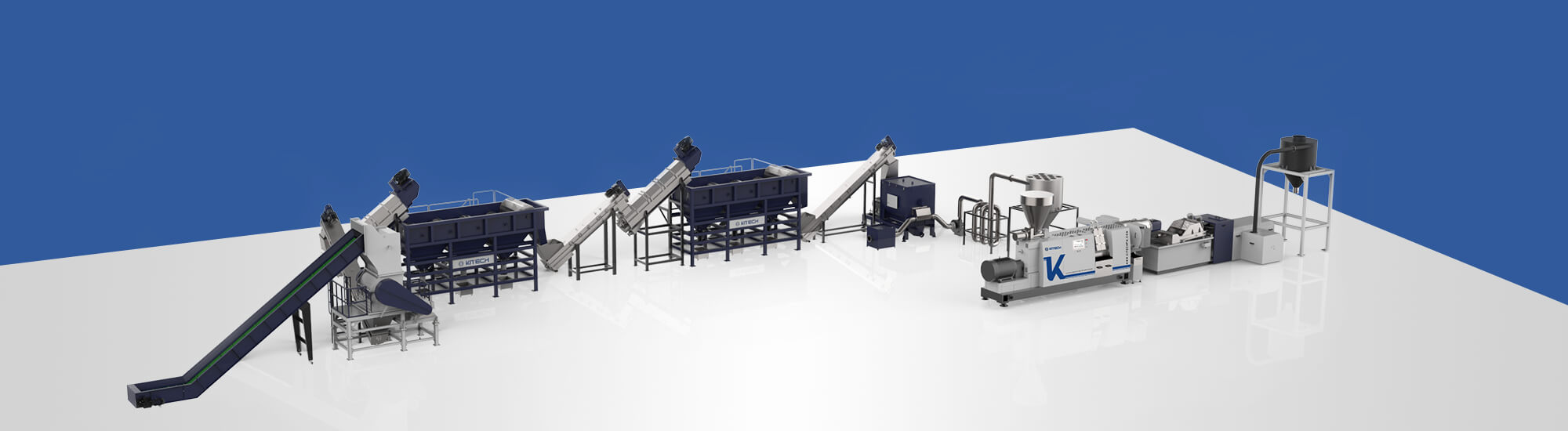

PP/PE bottle cans recycling line can treat with milk bottle,shampoo bottle which composition is PP,PE,LDPE,HDPE etc.

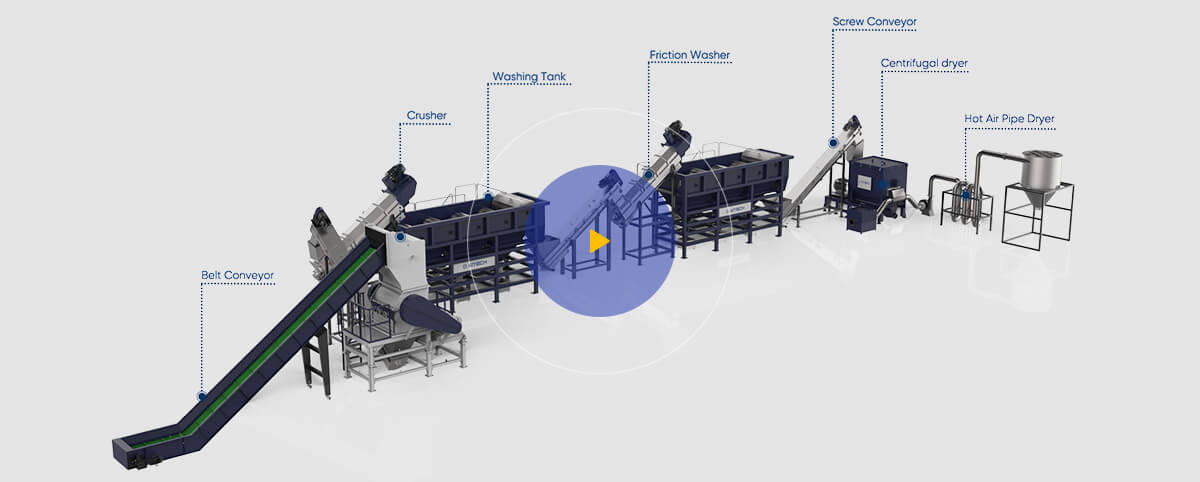

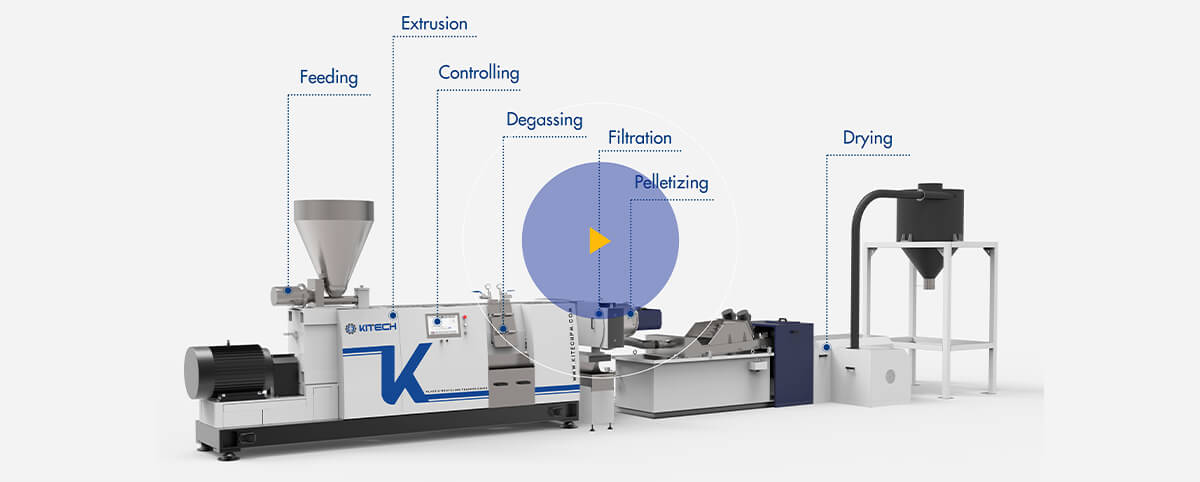

The whole process include crushing, water rinsing, friction washing, dring by washing system; plasticization, pelletizing and drying by pelletizing system. PLC intelligent system realized high automatic, the whole line just need 3-4 man to operate.

With 25 years of experience in recycling, KITECH not only mastered the key technology, but also improved machine designs to address specific product features. KITECH offers PP/PE bottles and cans recycling solutions that are high output and low energy consumption.