Reduce humidity level

Increase pelletizing efficiency

Improve granules quality

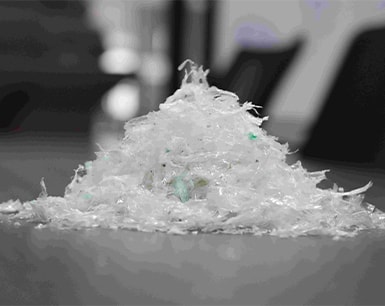

In generally, washed film can contain up to 40% moisture level and can be problematic for post-consumer recyclers. A typical horizontal type dryer can not effectively remove the water moisture from the light-weighted film scraps/flakes and there is 15-20% water moisture remaining in the material after drying usually. The excessive water content usually results in inconsistent feeding and low output in the pelletizing extruder.

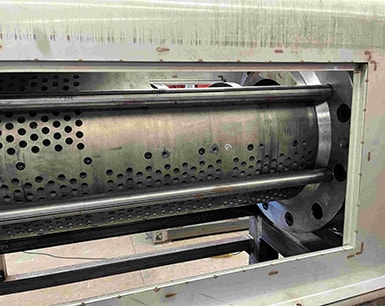

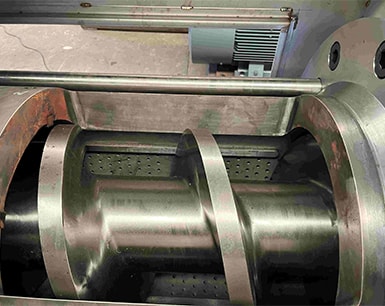

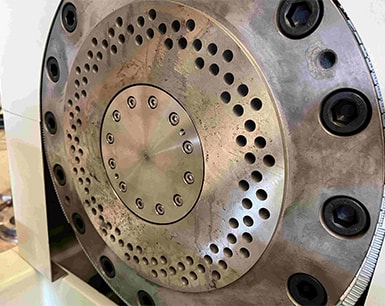

The squeezer drying machine offers a fast and efficient way to reduce water moisture level down to 3 ~5 % from 20~40% that reduce the pressure of recycling extruder.

The processing generates less heating which results in less material degradation, higher value and higher reusability of recycled pellets.

It turn film scraps into solid flakes–higher bulk density, less volume results in faster, easier and more stable and consistent feeding to the recycling extruder.

KITECH IS COMMITTED TO BECOMING A WORLD-RENOWNED RECYCLING EQUIPMENT MANUFACTURER.

TYPE | KSD300 | KSD 320 | KSD350 |

Screw diameter(mm) | 300 | 320 | 350 |

Drive power (kw) | 110 | 132 | 185 |

Cutting power(kw) | 4 | 5.5 | 5.5 |

Force feeder(kw) | 4 | 5.5 | 7.5 |

Output capacity(kg/h) | 300-500 | 500-800 | 800-1000 |

Humidity level(%) | 3-5 | 3-5 | 3-5 |

Fianl granules(mm) | 12-20 | 12-20 | 12-20 |