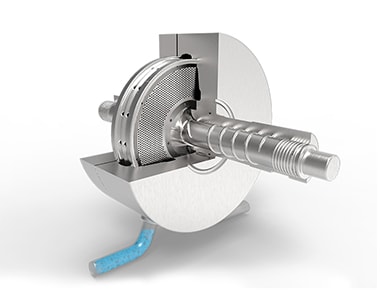

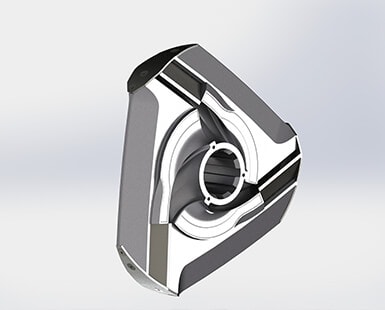

In post-consumer or post-industrial plastic wastes, like PP, PE, LDPE, HDPE, PS, EPS, ABS, PVB, soft PVC, many contamination type can be found such as iron/steel, wood, paper, textile fibres, Un-melted plastics, aluminium, sand, copper, stones, almost others.by the contaminations are constantly increasing and the traditional (manual) screen changers are not able to deliver a good quality of the final product. For this reason, it is necessary to switch to an automatic and continuous system.the Laser Filter is the most suitable filter to recycle contaminated plastics. It filters high levels of contaminations and can resist high pressures. The operator can therefore dedicate more time to an efficient feeding of the extruder, and does not to have to change filter screens before the pressure reaches the set point. It reduces the operational and labour costs. The Laser filter adapts to your material: depending on the MFI (from 0,124 to 200 g/10’) ,It improves your quality results and any level of filtration fineness is available, from 178 to 2000 micron (80 to 10 mesh).