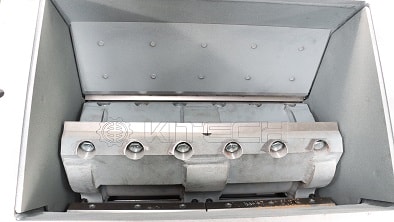

Optimally designed blades are sharp and powerful

Enclosed cutting chamber to prevent materials flying out

Knives are externally adjustable

20-40% additional throughput

Enclosed cutting chamber to prevent materials flying out

High efficiency and long operating cycle

Increased motor drive

long service time

Electrical hydraulic control to open housing

optional hard facing easy for exchange

Strong and durable

Knives are externally adjustable

D2 material

Anti-wear machine housing

High strength and toughness

Turn-key project solution supplier

The AGF PP PE Film Granulator has been specially design for the processing of LLDPE/LDPE/PP/BOPP Stretch film, agricultural film, mulching film,garbage bag, shopping bag etc.

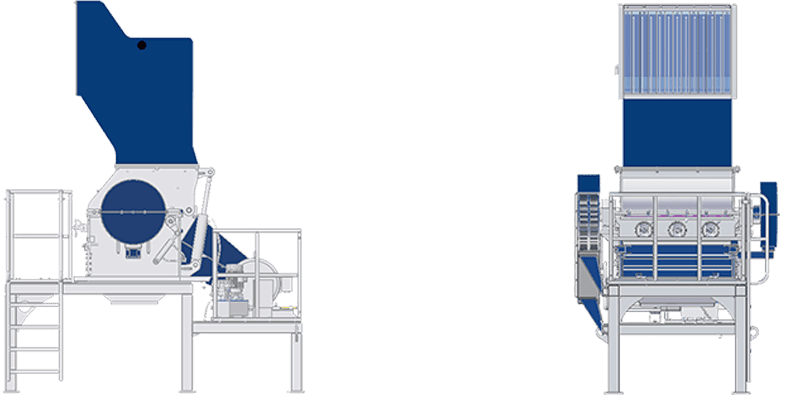

It has a centrally hinged two-piece cutting chamber with a robust welded steel construction, with the upper and lower sections of the housing meeting horizontally. Heavy duty paddle type rotor in welded steel construction,Driving rotor Knives installed in “V” Angle, “X” cutting shape. Reversible stator knives with double cutting edges are fitted as single elements to the lower section of the housing, allowing multiple re-sharpening and adjustment of the stator knives. There is a hinged screen cradle and hinged door for easy screen access.

The rotor is a heavy duty paddle type design with knife cover plates to protect the blades when processing abrasive applications. The knife mounting bolts are screwed into the mounting plates as opposed to the rotor. All knives are manufactured from chrome nickel tool steel as standard, but when processing applications that are particularly abrasive the AGF granulators can be fitted with a specially designed wear resistant rotor utilizing wear resistant steel parts and hardox facing.

The v-cut cutting geometry offers distinct advantages over other rotor designs, including higher throughput with reduced power consumption, better quality cut, and lower noise levels. The AGF rotor configuration provides between 20-40% additional throughput in comparison to standard rotor configurations.

Specially designed knife setting jig means that the knives can be adjusted from outside the machine, significantly reducing the downtime required to change/set knives.

The base frame has a solid welded construction with anti-vibration rubber feet to reduce vibration and noise. The drive motor is mounted on tension rails to allow easy adjustment of the V-belt tension. Integrated suction trough for material discharge.

Specially designed hopper with 3 sets of curtains to prevent material flybacks.

Integrated rundown safety device prevents access to the rotor until it has come to a complete stop. A safety switch prevents machine startup when the front panel is open and the machine features emergency stop buttons on the machine body and control panel.

KITECH IS COMMITTED TO BECOMING A WORLD-RENOWNED RECYCLING EQUIPMENT MANUFACTURER.

| item | utin | AGF500/700 | AGF700/1000 | AGF700/1200 | AGF800/1200 | AGF800/1600 |

|---|---|---|---|---|---|---|

| Cutting Chamber | mm | 500X700 | 700X1000 | 700X1200 | 800X1200 | 800X1600 |

| Rotor Diameter | mm | 500 | 700 | 700 | 800 | 800 |

| Rotor width | mm | 700 | 1000 | 1200 | 1200 | 1560 |

| Rotor Speed | rpm | 570 | 555 | 555 | 555 | 450 |

| Main Motor Power | kw | 55 | 75 | 90 | 132 | 160 |

Rotor Knives | pcs | 5*2 | 5*2/7*2 | 5*2/7*2 | 5*2/7*2 | 7*4/9*4 |

| Stator Knives | pcs | 2 | 2 | 2 | 2 | 4 |

| Hydraulic Ram Power | kw | 3.75 | 5.6 | 5.6 | 5.6 | 5.6 |

| Screen Size | mm | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 |

| Capacity | kg/hr | 300 | 500 | 700-800 | 1000-1100 | 1500-1800 |