BOPP Film

One stage with two times filtration cleaning

High automation self cleaning system

High capacity increased and low energy consumption

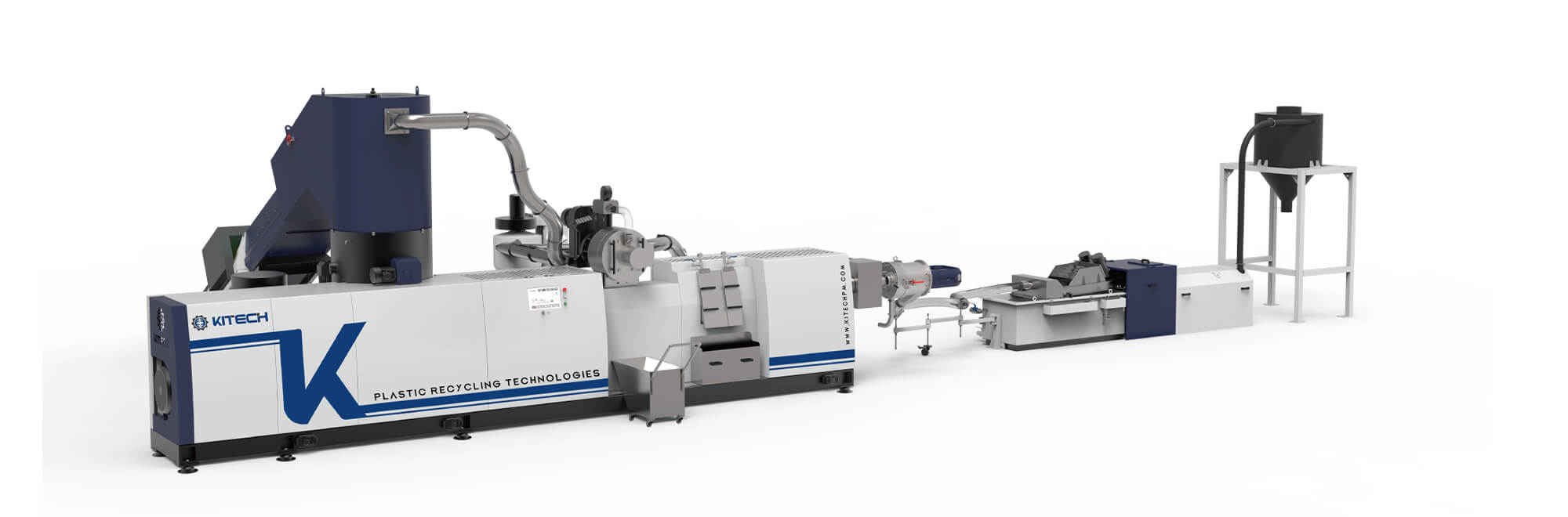

The KCP series Plastic recycling compacting and water ring pelletizing machine combines function of crushing, compacting, filtration and pelletizing into one step.

Compared with old generation pelletizing system, the throughput has increased by 50% and the energy consumption ratio has decreased by 20%.

It provides best solution for LDPE, LLDPE, HDPE, PP, CPP, BOPP, PS, EPS, XPS, ABS, POM, PA film, raffia, filament, bag, woven bag and foam materials recycling.

BOPP Film

Bubble Film

LLDPE Film

Shopping Bag

Washed Film

Waste Bag

HDPE Regrind

Nonwoven Fabric

EPS Foam

Woven Fabric

Filament & Yarn

Squeezed Film

| Machine Model | New 5G KCP180 Plus |

|---|---|

| Brand | KITECH |

| Applicable material | LDPE, LLDPE, HDPE, PP, BOPP, CPP, EPS, PS, PPS, ABS, PA, PLA |

| Capacity | 600-1500KG/H |

| Screw diameter | 100-180MM |

| Screw design | Single Screw |

| L/D ratio | 50 |

| Screw rpm | 94-120 |

| Screw material | 38CrMoAl |

| Gearbox type | High torque vertical |

| Motor brand | WEG/SIEMENS |

| Filtration system | 2 |

| Degassing zone | 2 |

| Pelletizer type | Water ring pelletizer |

| Total power | 450-954KW |

| Delivery time | 3-4 months ready for inspection |

| Guarantee | 1 year |

| Certificate | CE/UL/CSA |

we are your best business solution

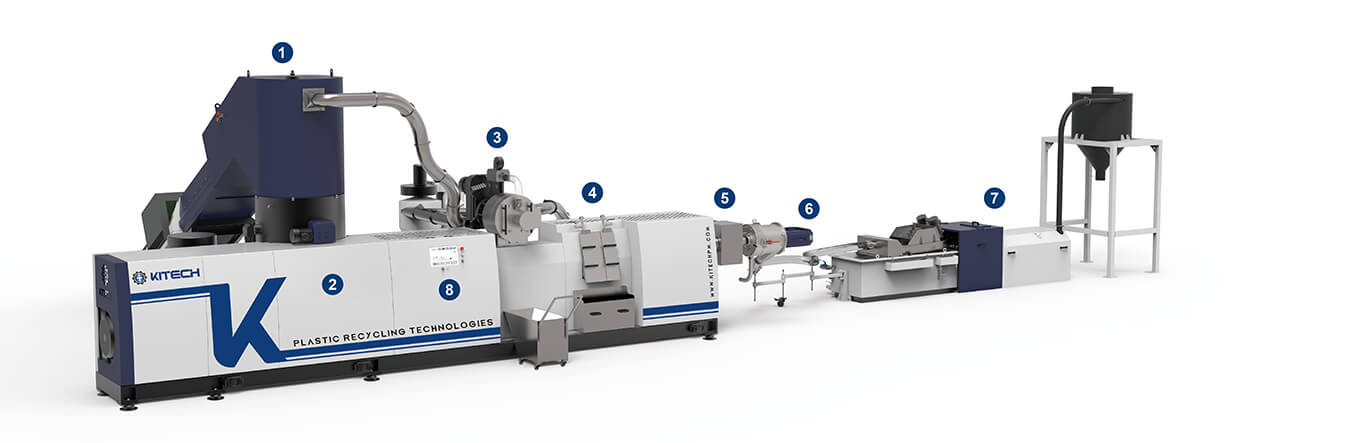

The plastic material got cutting, mixing and preheating in compactor uniformly, to ensure the material heated and dried effectively.

Synchronous motor and driver, energy saving rate 8% - 12%. Intelligent heating system and intelligent temperature control system can save energy by 5%. Screw L/D ratio 50:1, The throughput has been greatly improved. Optimized vacuum degassing system ensures high effective venting of volatile.

The continuous self-cleaning filter is suitable for materials with high contamination. Double screens design with high throughput. It can use for long periods without changing the screen. Another filter can be installed at end of extruder to achieve two stage filtering.

Force double vacuum degassing system to get rid of the low molecular, moisture and printing ink effe -ctively, make sure high quality output pellets.

Plate type, piston type, back flush type and automatic self-cleaning type filter, you have different choice according to impurity contents in material and your habit.

Water ring pelletizer, strand type pelletizer, automatic strand pelletizer and under water pelletizer, KITECH provides different types of pelletizing solutions. For different MFI polymers and different users. High quality and stable throughput pellets.

Vibration dryer combined with horizontal type centrifugal dryer to get well dried final granules.

The DAS system supports data downloading and storage to help users achieve centralized monitoring of intelligent workshops. AMS provides protection procedures and maintenance videos to improve the service life of the machine. HMI intelligent operating system is easy to operate. The remote system supports remote diagnosis and provides mechanical, process and electrical integrated remote services.

KITECH IS COMMITTED TO BECOMING A WORLD-RENOWNED RECYCLING EQUIPMENT MANUFACTURER.

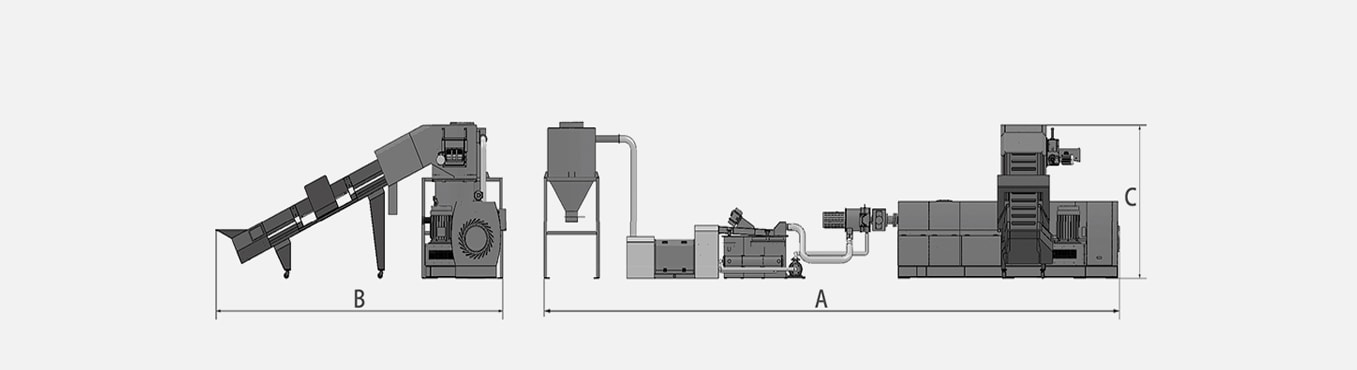

| TYPE | 5G KCP100/50 | 5G KCP120/50 | 5G KCP160/50 | 5G KCP180/50 | |

|---|---|---|---|---|---|

| Capactity (KG/H) | 300-600 | 500-800 | 900-1200 | 1200-1500 | |

| Energy consumption (kwh/kg) | 0.32 | 0.32 | 0.32 | 0.32 | |

| A / Length (mm) | 10,300 | 13,080 | 17,040 | 17,320 | |

| B / Width (mm) | 6,200 | 6,450 | 6,850 | 6,850 | |

| C / Height (mm) | 3500 | 3980 | 4460 | 4850 | |

| Compactor | Volume (L) | 800 | 1000 | 1400 | 1600 |

| Motor power (KW) | 110 | 160 | 200 | 250 | |

| Extruder | Screw diameter (mm) | Φ100 | Φ120 | Φ160 | Φ180 |

| L/D | 50 | 50 | 50 | 50 | |

| Motor power (KW) | 185 | 250 | 355 | 400 | |

| Intermediate laser filter | Filtration diameter (mm) | 350*2 | 365*2 | 500*2 | 700*2 |

| Second filter (options) | Two position plate type | ◉ | ◉ | ◉ | ◉ |

| Two position piston type | ◯ | ◯ | ◯ | ◯ | |

| Back flush piston type | ◯ | ◯ | ◯ | ◯ | |

| Automatic self-cleaning type | ◯ | ◯ | ◯ | ◯ | |

| Downstream (options) | Water ring pelletizer | ◉ | ◉ | ◉ | ◉ |

| Strand pelletizer | ◯ | ◯ | ◯ | ◯ | |

| Automatic strand pelletizer | ◯ | ◯ | ◯ | ◯ | |

| Underwater pelletizer | ◯ | ◯ | ◯ | ◯ | |

◉ Standard ◯ Alternative