JIANGSU KITECH MACHINERY CO.,LTD

Landfill: Because of the macromolecular structure, waste plastics are not easy to decompose and rot after being discarded. They are light in weight and large in size. They can fly with the wind or float in the water when exposed to the air. Therefore, people often use hilly recesses or natural depressions to build landfills and sanitary landfills. The sanitary landfill method has the characteristics of low construction investment and low operating cost, and has long been a method of disposal of waste plastics widely used in countries all over the world. However, landfill treatment has serious shortcomings: plastic waste has a large area due to its low density and large volume, which increases the burden of land resources.

Incineration: Incineration to recover heat energy is another major method of waste plastic disposal. The treatment method of incinerating waste plastics has the advantages of large processing quantity, low cost and high efficiency. Compared with direct landfill, incineration treatment effectively utilizes waste plastics and has turned waste into treasure. However, there are also many shortcomings in incineration treatment: with the change of plastic types and incineration conditions, waste plastics will produce polycyclic aromatic hydrocarbons, carbon monoxide and other harmful substances during the incineration process, such as PVC will produce HCL, polyacrylonitrile will produce HCN, And so on, these substances have caused pollution to the environment. Waste plastics also contain heavy metal compounds such as cadmium and lead. During the incineration process, these heavy metal compounds will be discharged together with soot and incineration residues, which also pollutes the environment.

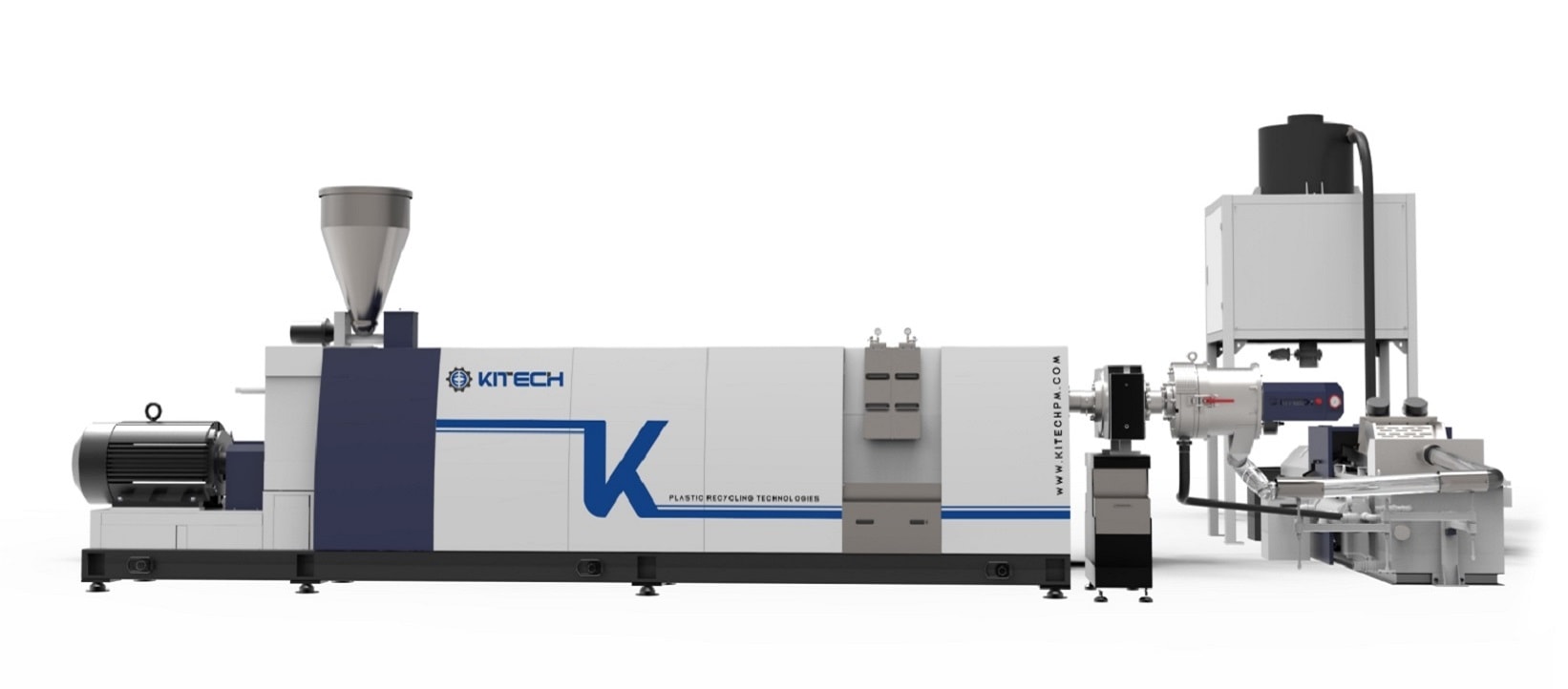

Recycled pellet manufacturing: Recycling waste plastics to produce recycled plastic pellets is a major advancement in waste plastic recycling technology. Using special pelletizing equipment, waste polyethylene, polypropylene and other plastics can be processed into market-selling recycled pellets through crushing-cleaning-heating plasticization-extrusion molding processes. Compared with simple landfill and incineration, recycled plastic particles can be reused as raw materials in the plastics industry, realizing resource recycling in the true sense. The industry in my country that uses waste plastics for the manufacture of recycled plastic pellets started early and has made great contributions to resource conservation and environmental protection. But on the other hand, the vast majority of enterprises in my country have always been in small-scale, disorderly production and operation methods, and there are still many problems: because most waste plastic processors are scattered, most of them still stay in low, small, scattered, and chaotic. It is in a three-in-one family workshop-style production and operation mode that integrates production, housing, and warehouse. The narrow and simple production site, coupled with the random stacking of flammable materials, has many potential accidents and it is difficult to ensure safety.

A large number of pollutants will be generated during the processing of waste plastics. Since most manufacturers of recycled plastic pellets have not yet realized the pollution problem and lack the necessary pollution control conditions, the waste water, impurities and residual waste generated are generally untreated. It is directly discharged, incinerated or discarded at will, which seriously pollutes the surrounding environment.