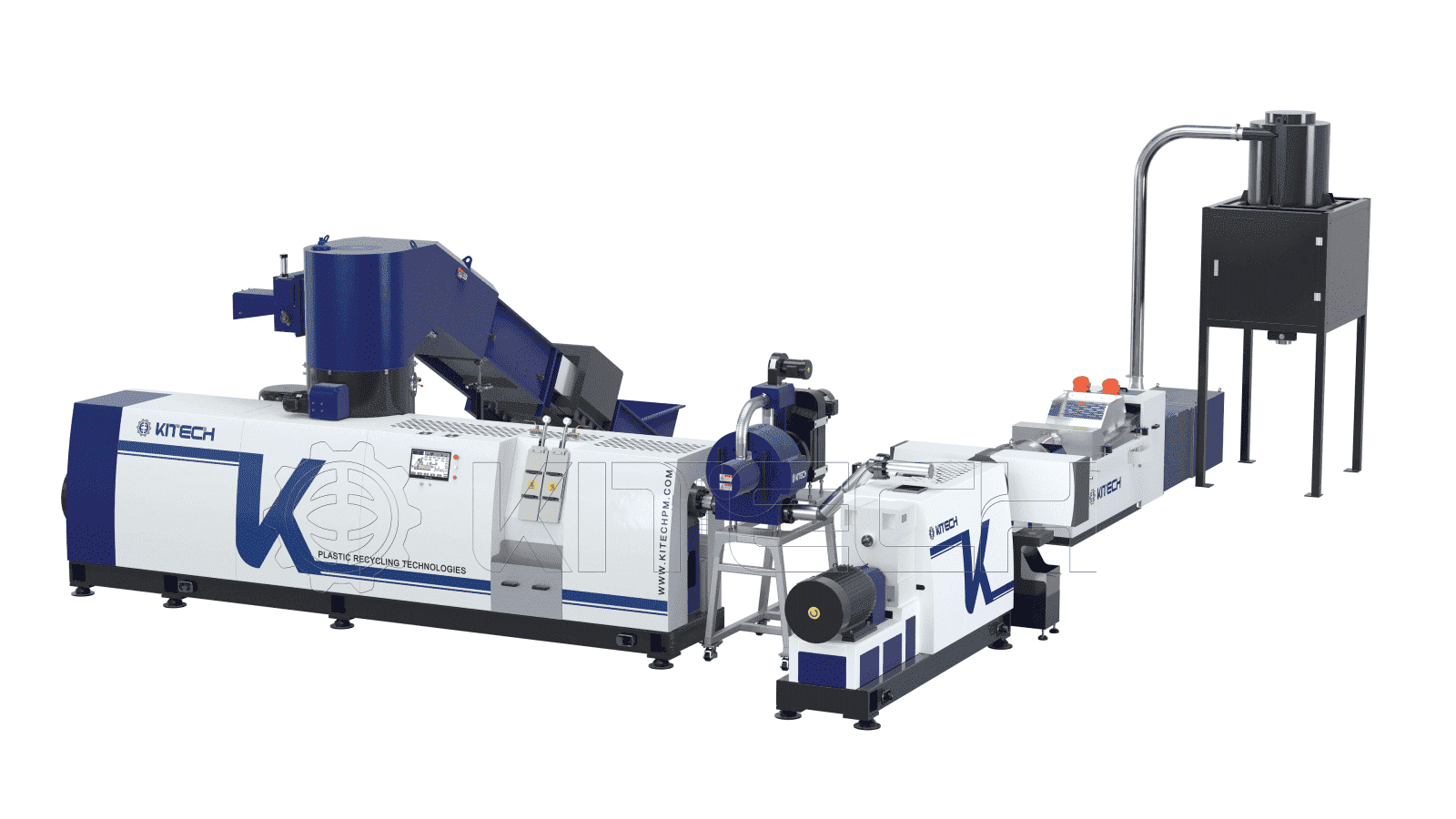

JIANGSU KITECH MACHINERY CO.,LTD

In this very competitive plastics processing industry where your production efficiency is life or death for your company, the best plastic pelletizing line supplier would be that individual who would make your production productive and efficient. The perfect seller would not just give you the equipment that will give you better performance but would also stand by your side for long-term maintenance, tailored solutions, and a safe workplace. With that many such stores to choose from, then, how in the heck do you ever even know who is actually best for your business?

Nowadays in this post, we'll be discussing five most crucial aspects to watch for while selecting a manufacturer of plastic pelletizing line – from credentials check and specifications on machines up to observing the level of being treated well once the sales have passed and how people actually have something to say about them. Either you're setting up a brand-new manufacturing line or prefer to switch over to a new design, all these resources will help you make an educated, informed decision.

| Certification | Description | Business Value |

| CE (EU compliance) | Demonstrates machinery meets EU standards for safety, health, and environmental protection | Required for European markets, indicates adherence to strict legal frameworks |

| ISO 9001 | Global benchmark for quality management systems | Shows the supplier uses consistent manufacturing processes and quality controls |

| SGS / TÜV / BV | Independent inspection and testing services | Offers third-party validation of machine performance, build quality, and safety |

| UL / RoHS (optional) | Safety and environmental certifications, especially for electrical components or export compliance | Enhances reliability when dealing with North America or eco-regulated markets |

Plastic pelletizing experience is not a function of years of business — it's a function of depth of projects completed, markets addressed, and range of technical challenges overcome. An experienced supplier has likely built dozens (if not hundreds) of lines for clients across many industries, which gives them insight into:

·Raw material behavior (e.g., rigid vs. flexible plastics, sorted waste, industrial scrap)

·Optimized line design for throughput range (100–2000kg/h)

·Long-term savings with energy-saving solutions

·Dust containment, noise reduction, and integration of automation for the factory of today

What a seasoned supplier would most likely deliver is the following:

| Aspect | Benefits to You |

| 10+ Years in Manufacturing | Proven stability, tested designs, and continuous improvements |

| Global Export Experience | Familiarity with packaging standards, shipping regulations, and installation support |

| Diverse Client Base | Ability to adapt machines for different raw materials and product specifications |

| After-Sales System | Pre-trained engineers, spare parts availability, and multilingual communication |

B2B equipment sourcing trust comes from track record and transparency. Any good supplier will never be afraid of:

·Providing factory audit reports or copies

·Providing you with real customer projects (backed up by video/photo evidence)

·Having you visit the factory (or doing live video factory tours)

·Trying out your material before shipping it

All that information de-risks your investment and guarantees that the supplier will be able to meet your own custom production requirements.

| Specification | What It Means | Why It Matters |

| Output Capacity (kg/h) | The amount of plastic pellets produced per hour | Must align with your daily production volume; available from 100 kg/h to 2000+ kg/h |

| Material Compatibility | Types of raw materials the machine can process (PP, PE, PET, ABS, etc.) | Ensures flexibility and stability with your current and future material sources |

| Screw Diameter & L/D Ratio | Size and length-to-diameter ratio of the extruder screw | Affects mixing efficiency, output pressure, and material residence time |

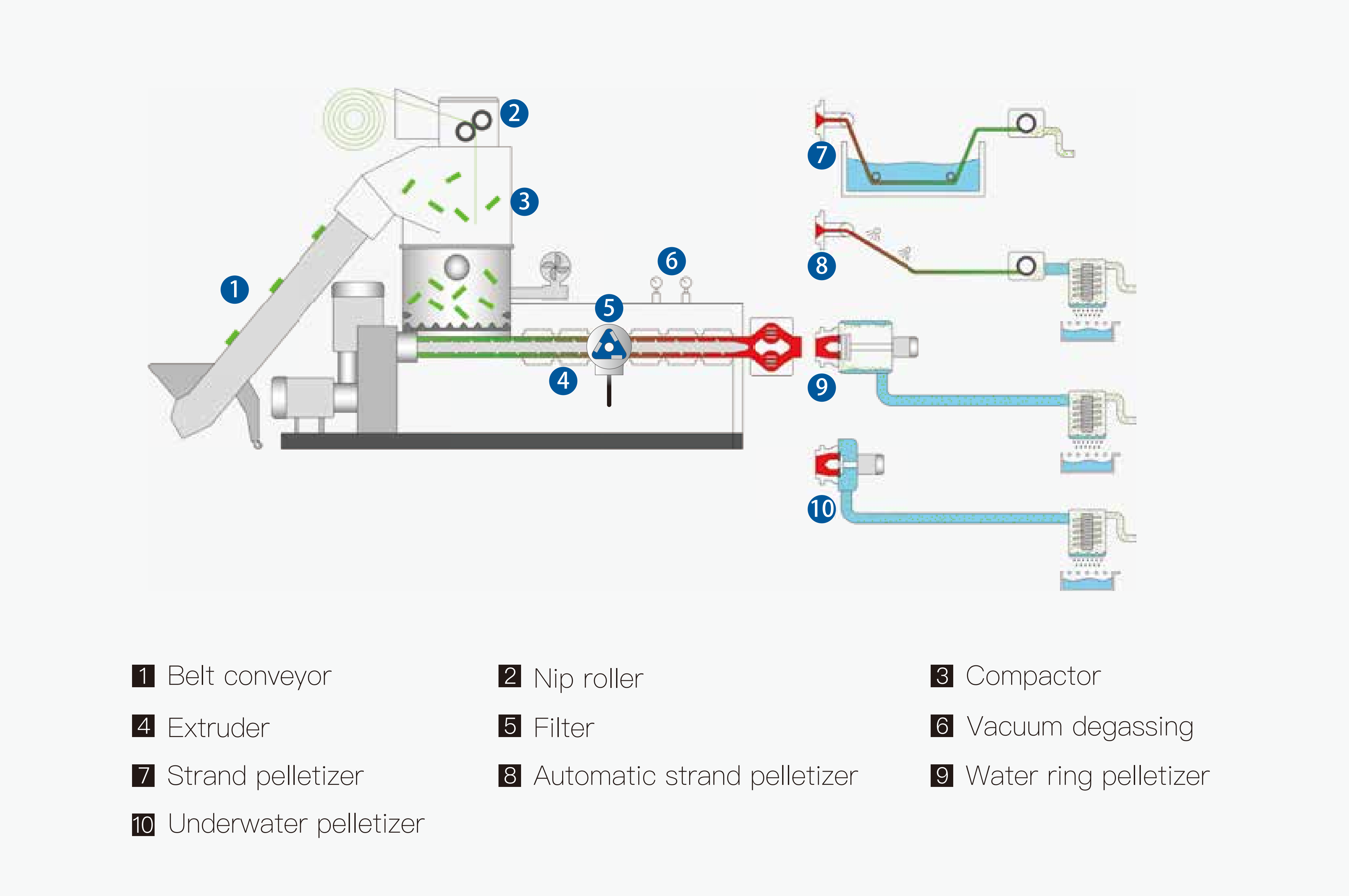

| Pelletizing Method | Types include strand, water-ring, underwater, air-cooling, etc. | Different methods suit different materials and desired pellet shapes |

| Motor Power (kW) | The power of the main drive motor | Impacts energy consumption and overall system torque |

| Automation Level | Manual, semi-automatic, or fully automatic control systems | Higher automation improves production consistency and reduces labor costs |

Your pelletizing line must be tailored to your most handled materials. Your reliable supplier will adapt screw design, temperature zones, and cutting method based on material type.

Common Plastic Types:

| Material | Typical Application | Processing Considerations |

| PP | Woven bags, injection molding waste | Moderate temperature, water-ring pelletizing preferred |

| PE | Film scrap, shopping bags, pipe offcuts | Requires strong degassing system, especially for LDPE |

| PET | Bottle flakes, textile fibers | Needs vacuum venting and crystallization unit |

| ABS/PC | Electronic waste, auto parts | Sensitive to temperature, requires precision control |

Whether you’re running a small-scale operation or a high-output recycling facility, matching your machine’s capacity to your production needs is essential. Here’s a general reference:

| Application Scale | Recommended Output Capacity | Machine Type |

| Small workshop/startup | 200–500 kg/h | Cutter compactor water-ring cutting or strand cutting |

| Medium-sized plant | 500–800 kg/h | Cutter compactor water-ring cutting or underwater cutting |

| Large-scale production | 1000+ kg/h | Cutter compactor water-ring cutting or underwater cutting |

In today's competitive manufacturing environment, one-size-fits-all may not be possible. A true qualified plastic pelletizing line supplier won't just provide off-the-shelf machinery, but also tailor solutions to your specific operating needs — from plant layout and raw material characteristics to automation wishes and downstream requirements.

Here is how customisation and solution support can really enhance your production performance.

Every factory has unique space constraints. A good supplier will:

·Evaluate your existing workshop layout

·Design a pelletizing line that fits seamlessly into your production flow

·Offer 2D/3D layout drawings before final confirmation

| Layout Feature | Customization Options | Benefits |

| Machine orientation | Inline, L-shape, or U-shape arrangements | Improves material flow and operator access |

| Height and hopper placement | Adjustable based on ceiling height and feeding method | Prevents material blockages or manual lifting risks |

| Centralized control panels | Positioning for multiple operators or zones | Enhances workflow and safety |

New plants are designed to reduce dependence on human staff and to achieve higher consistency and control of information. Best-of-breed vendors are able to provide smart control systems to your pelletizing line, for instance:

·Real-time monitoring PLC + HMI systems

·Remote diagnosis of the IoT module

·Automated feeding, cutting, and drying units

·Quality control and traceability through the recording of production information

| Smart Feature | Function | Benefit |

| PLC Touch Screen | Centralized operation with visual interface | Simplifies control, reduces training time |

| Alarm & Safety Systems | Real-time fault detection and auto-stop | Prevents equipment damage and improves safety |

| Variable Speed Drives (VFDs) | Adjustable motor speeds | Saves energy, enhances process flexibility |

High volume suppliers know the growth of a business cannot be halted. Hence, modular system design is the basis of everything

·Provides direct upgradability (e.g., addition of an extra filtration unit or auto-packaging unit)

·Lower initial cost — you start later

·Reduces downtime if changes are required

It is the best strategy for those businesses wishing to increase capacity in discrete increments or according to evolving recycling regulations.

A quality start-up is the key to success in long-term business. Quality suppliers offer:

·Site installation details or full set-up service

·Line commissioning to optimize best performance

·Processing calibration of certain raw materials.

·Pre-handover safety verification and fault-checking prior to official handover

| Service Item | Description | Benefit |

| Installation Supervision | Engineers assist or manage full installation | Reduces risks during setup |

| Trial Production | Running tests using customer’s raw material | Ensures machine is tailored and well-tuned |

| Parameter Optimization | Adjustment of speed, temperature, and cutter speed | Maximizes output and pellet quality |

Spare parts availability is the top concern for customers in most industries. Ensure your supplier possesses:

·Small spare parts kit shipped with first shipment

· Rapid replacement inventory planning of major-wear items such as blades, heaters, sensors, etc.

·International customs clearance shipping service

| Spare Part | Typical Lifespan | Recommended Replacement Frequency |

| Blade of compactor | 6–12 months | Keep at least 1 set in stock |

| Pelletizing Blades | 7–10days | Keep at least 100pcs in stock |

| Heaters | 6–12 months | Inspect quarterly |

| Seals | 6–12 months | Replace every 6–12 months |

| Filtraction screen | 10minutes-4hours | Keep at least 200pcs in stock |

| Laser filter screen | 2-3months | Keep at least 2 sets in stock |

| Touch Panel/PLC Parts | 2+ years | Keep critical backups |

Because the whole world is now being networked, after-sales service no longer stops at your factory gate today. All best-in-class suppliers today need to provide:

·Ethernet or Wi-Fi-based PLC systems for wireless troubleshooting and diagnosis

·Repair or emergency video support

·Cloud-based data tracking and maintenance reminder

This service offsets downtime, especially where slow-to-react on-site repair has taken place.

Choosing the right plastic pelletizing line supplier is not always a cost issue — it's about doing business with a supplier who understands your business, listens to your manufacturing objectives, and offers long-term value. By pitting important factors like certification of the supplier, machine capacity, customization compatibility, after-sales support, and reputation of the customer against each other, you can make an informed decision for your business in the future.

It is your key to profitability whether you are starting or already have a running plastics recycling plant. Delay not in your decision — reward will be an efficient, productive profit-generating production line.