HDPE bottle,drums

Programmable Control

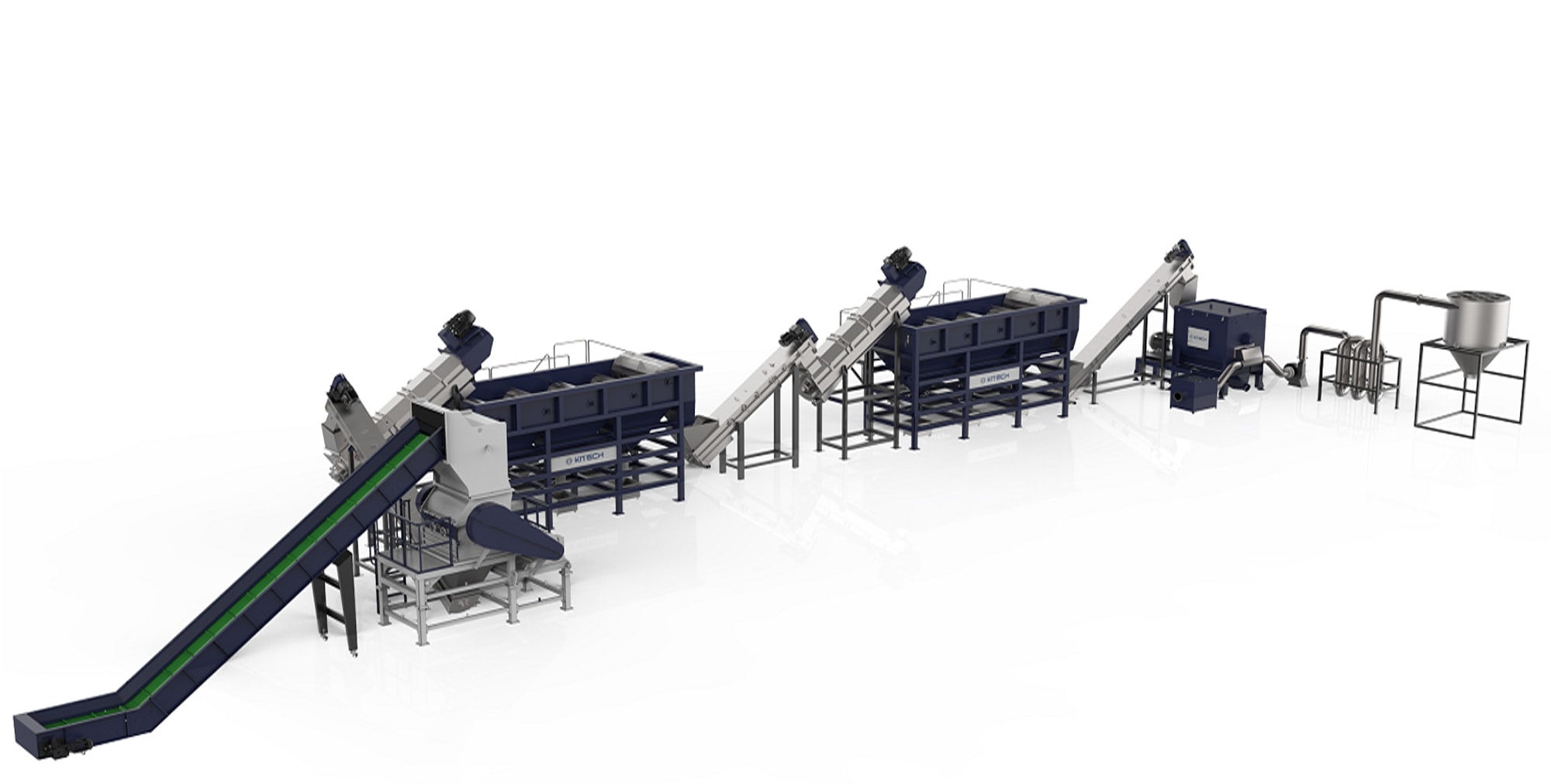

Modular Combination Installation

Multiple Materials Process

HDPE bottle,drums

HDPE bottle,drums

HDPE bottle,drums

HDPE bottle,drums

Turn-key project solution supplier

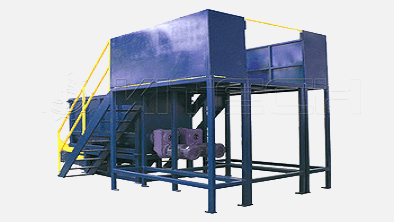

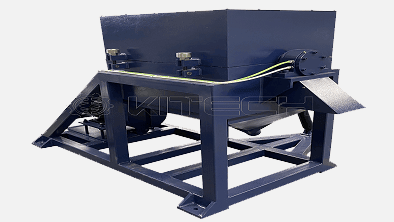

Pre-processing modular is freely consists of bale breaker,screen,pre-washer,sorter,metal detector,label remover,and some other equipments. It provides pre-treatment for the raw material.

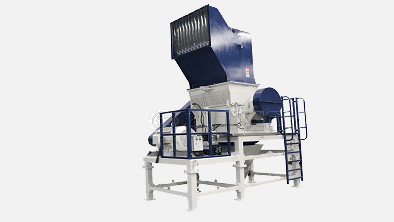

Large materials are processed into small pieces in this modular, which improves the washing result and makes the final product easy to packing.

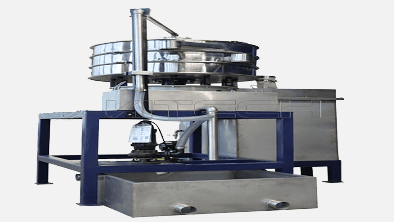

Dust, glue, label,oil and other impurities can be removed highly effective by washing mod -ule. This modular combines foating washing, hot washing, salty water separating, high-speed friction washing, low-speed friction, spraying, and some other washing equipments.

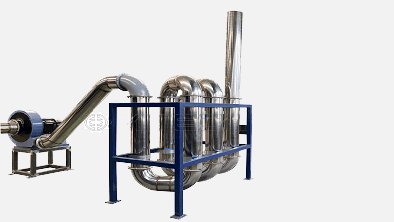

Squeezing and drying treatment is used to remove the moisture in the material with low packing density. Mechanical dewatering treatment is used to process the material with high packing density to reduce energy consumption.

Near Infrared Spectrum , Aerodynamic principles material, and many other technology is used to separate material, color, and specific gravity to purify and sort products.

Weighing and metering system helps you monitor the output and energy consumption of production line in real time under different materials and production conditions. All data can be connected to ERP system for quantitative assessment. Which ensures that we can update and maintain all user's systems for a long term.

Speed driving by frequency inverter;

Heavy built shaft and balde;

Double shafts designs;

Permanent magnet belt;

SEW Eurodrive reducer;

High magnetic field strength;

Speed driving by frequency inverter;

Strong heavy frame structure inside;

Heavy duty type, adopt gear motor;

Side walls to avoid spilling of feeding material;

Optimally designed blades are sharp and powerful;

Enclosed cutting chamber to prevent materials flying out;

Knives are externally adjustable;

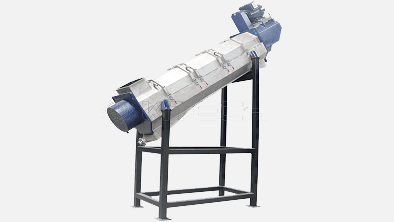

Screw adopt wear resistant stainless steel;

Triple sealing, External bearing design;

Rotor and blades adopt wear resistant steel;

Rotor with dynamic balance treatment. Accuracy: ±3-5g;

Active material washing to protect downstream units;

Thumb-wheel speed variable by inverter control;

Non-stop on line sediment discharge;

All part touch raw materials are stainless steel;

All Thumb-wheel speed variable by inverter control;

Heavy duty washing, separation of different specific densities material;

All part touch raw materials are stainless steel;

Rotor with dynamic balance treatment. Accuracy: ±3-5g;

Mild circular screen in polygon 4 piece version;

Washer/dryer housing built in stainless steel welded construction;

Multi-layers vibration screen ;

Impurities filtration from discharged water;

Pipeline built in stainless steel welded construction;

All part touch raw materials are stainless steel;

Hot air drying system;

Zigzag structure;

Air flow speed variable by inverter control;

All part touch raw materials are stainless steel;

International brand Low voltage components ;

Double circuit safety relay;

Intelligent and modular PLC controlling system

KITECH IS COMMITTED TO BECOMING A WORLD-RENOWNED RECYCLING EQUIPMENT MANUFACTURER.

Thanks to inovtive、washing technology and high quality recycling and estfrmanen KITech iellgent washing systen removes the ngest diffhcult soninente from waste plsss for customers.

KITECH washing system is available for 24 hours working non-stop operation. Optimized design and top brand components to each unit. Which could minimize the downtime ratio and save the maintenance time. This ensures the maximum availability and highest productivity for user.

KITECH washing system is designed in all details for effciency improving. The modular design could simplifty the planning and aooelerate the implementation." The system have very low consumption values for electricity, water and labor.The operating costs and maintenance costs are absolutely reduced. Consistently the lowest investment costs and highest value creation.

KITECH washing system is a flexible modular system. The process required by any customer for different application could be combined freely. This design reduces planning, construction and assembly time effectively. And it's possible to adjust the system regard to technological modifh -cation and market changing. This makes the investment future-proofing.

Automatic control of KiTech washing system reduces the labor operation, makes the whole system easier and more reliable to control, the remotes monitoring and maintenance are available for different production line. The intelligent control has display for operating data, it also collect the data of the consumption and the capacity from production lines. Which ensures the connection between the enterprises and the Internet, will improve the efficiency of enterprise management.

KiTech washing system is a flexible and customer- oriented recycling solution. All the components of the whole line is globally well- known brands, which ensures the reliable operation and serves your exact needs. Furthermore, our engineers will partner with you for the whole project. Building design, overseas installation, commissioning and training are available. Machine warranty with spares in stocking and in-time delivery. Consistently quick and careful service in pre-sales and after-sales process.

| Technical parameter | |||||

|---|---|---|---|---|---|

| Type | RPW500 | RPW1000 | RPW2000 | RPW3000 | |

| Capacity (kg/h) | 500 | 1000 | 2000 | 3000 | |

| Energy consumption (KWH) | 127 | 176 | 271 | 316 | |

| Installation power (KWH) | 196 | 270 | 417 | 487 | |

| Steam consumption (kg/h) | 300 | 500 | 500 | 500 | |

| Dimension: L*W*H (m) | Depends on factory layout | Depends on factory layout | Depends on factory layout | Depends on factory layout | |

| De-baler | Unpacking motor power (kw) | 7.5 | 11 | 15 | 18.5 |

Processable bale size: L*W*H (m) | 1.0x1.0x1.2 | 1.1x1.1x1.3 | 1.1x1.1x1.3 | 1.4x1.4x1.8 | |

| Magnetic belt | Drive motor | 2.2 | 2.2 | 2.2 | 2.2 |

| Magnetic field strength | 760 GS @ 250 mm | 760 GS @ 250 mm | 760 GS @ 250 mm | 760 GS @ 250 mm | |

| Trommel | Diameter (mm) | 1000 | 1200 | 1500 | 1800 |

| Screen size (mm) | 20-50 | 20-50 | 20-50 | 20-50 | |

| Belt conveyor | Belt width (mm) | 800 | 800 | 1000 | 1200 |

| Motor power (KW) | 2.2 | 2.2 | 3 | 3 | |

| Crusher | Grind chamber (mm) | 500*700 | 700*1000 | 800*1200 | (700*1200) |

| Motor power (KW) | 55 | 75 | 132 | 90*2 | |

| Screw conveyor | Screw diameter (mm) | 250 | 300 | 400 | 500 |

| Motor power (KW) | 2.2 | 3 | 4 | 5.5 | |

Friction | Screw diameter (mm) | 300 | 400 | 500 | 600 |

| Motor power (KW) | 11 | 18.5 | 30 | 37 | |

Hot | Dimension of tank (m) | Φ1.6m×2.2m | Φ1.8m×2.4m | (Φ1.8m×2.4m)*2 | (Φ2m×2.5m)*2 |

Agitator motor power | 15 | 22 | 22*2 | 30*2 | |

Washing | Dimension of tank (mm) | 5000mm×1200mm | 6000mm×1600mm | 8000mm×1800mm | 10000mm×1800mm |

No. of thumb-wheel | 5 | 6 | 8 | 5 | |

| Centrifugal dryer | Rotor diameter (mm) | 460 | 500 | 550 | 650 |

| Motor power (KW) | 15 | 22 | 30 | 45 | |

| Waste water filtration device | Vibration screen size | 1000 | 1000 | 1200 | 1200 |

| Screen mesh | 40 | 40 | 40 | 40 | |

Hot air | Pipe diameter (mm) | 133 | 159 | 169 | 219 |

| Heating power (KW) | 36 | 36 | 48 | 55 | |

Label | Drive motor (KW) | 3 | 4 | 4*2 | 5.5*2 |

| Electrical | PLC controller | ◯ | ◯ | ◯ | ◯ |

| cabinet | Button type | ◉ | ◉ | ◉ | ◉ |

| Color sorter | ◯ | ◯ | ◯ | ◯ | |

| Man power (person/shift) | 3-4 | 4-5 | 5-6 | 6-8 | |

| Delivery time (day) | 60-70 | 70-80 | 80-90 | 100-110 | |

| Warranty (month) | 12months | 12months | 12months | ||

| Technical assistance | Egnineer available to service machinery overseas | Egnineer available to service machinery overseas | Egnineer available to service machinery overseas | Egnineer available to service machinery overseas | |

◉ Standard ◯ Alternative - Fixed